Metal Halide Lamps

An HID light source with great color rendering

Commercial History (1960 - Today)

Metal halide lamps are a powerful source of light. Photo: 379th Air Expeditionary Wing, US Air Force

Introduction & Statistics

Design Variations

Inventors and Developments

Introduction:

This type of lamp is also known as an 'MH' lamp. It is an HID lamp (High Intensity Discharge), which means it provides most of its light from the electric arc within a small discharge tube. It is becoming increasingly popular due to its good quality white light and good efficiency. The most prominent use of the MH lamp is in stadiums and sports fields. It is also used widely for parking lots and street lighting in urban areas. Its competitors include the HPS lamp, mercury vapor lamp, LPS lamp, halogen lamps, and LEDs. MH lamps have advantages over the rest which make it more useful for certain applications.

All credits and sources are located at the bottom of each lighting page

Advantages:

*More pure white light than the popular HPS lamps, close to daylight frequencies, which allows it to be used for growing plants

*More energy efficient than mercury vapor and halogen lamps, great lumen output

*Good for indoor (high ceiling areas - "high bay" applications) and outdoor use due to good light quality

Disadvantages:

*Expensive per-bulb cost: expensive to manufacture - many parts to assemble and materials are not cheap

*Light pollution: the light is so bright that it produces much more light pollution than HPS or LPS street lamps, the whites from an MH lamp are closer to daylight in frequency.Video on MH lamps. 8 minutes. YouTube must not be blocked on your server and flash plug-ins required.

Statistics

*Lumens per watt: 65 (large bulbs) up to 115 (small HP MH bulbs) (25% of energy makes light, 75% heat)

*Lamp life: 20,000 hrs (when mounted base up)

10,000 hrs (horizontal mounted)

*CRI 60 - 90 (depends on brand and chemical compositions)

*Color Temperature: 3000 (warm white) - 20,000K (blue)

Warm up time: 1 - 15 minutes

Common uses: outdoor lighting where good color rendering is needed, television/film lighting, sports fields, car headlights, flood lights, heavy flashlights, green house applications

1. How it Works 2. Variations & Uses 3. Inventors & Developments

1.) How it Works:

The lamp uses mercury vapor to create the powerful light (like the high pressure mercury vapor) but includes other metals (halide salts) to improve the color.A Halide is a chemical compound of a halogen combined with an electropositive element, or in the case of lamps: a metal. A halogen is a monovalent element which readily forms negative ions. There are 5 halogens: fluorine, chlorine, bromine, iodine, and astatine.

Halide 'salts' used in the MH lamp include:

Hg (Mercury) - bluish

AgCl - white

AgF - no color

AgBr - pale yellow

Agl - green yellowNormal MH Lamp Operation (not pulse start)

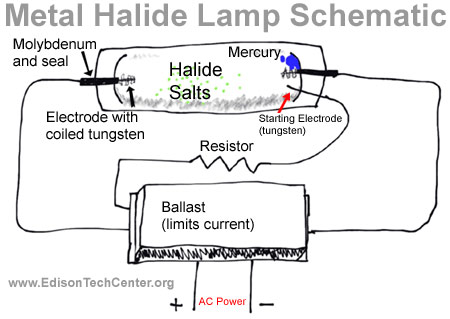

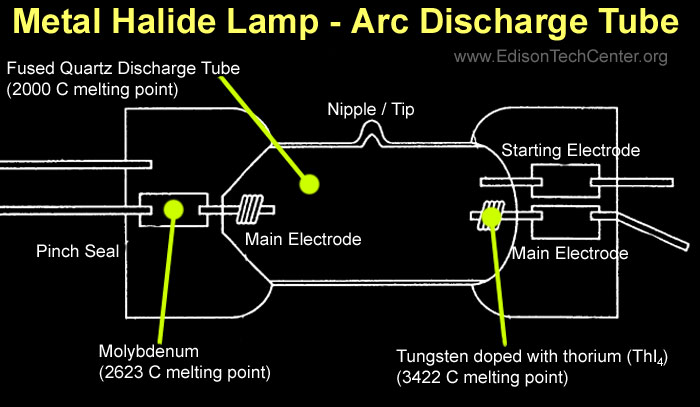

1.) When the lamp is cold the halides and mercury are condensed on the fuzed quartz tube. When the lamp is turned on current passed through the starting electrode and jumps the short distance to the main electrode (see the diagram below), this is aided by argon gas. The argon gas strikes an arc at low temperatures. (You can also see the 8 minute video on this page which includes animated graphics how it works)

2.) After the initial small arc the tube heats up and the mercury is vaporized. Electric arcs fight to work through the resistance of a gas, but over time more molecules of the gas become ionized. This makes it even easier for more electric current to pass through, so the arc gets wider and hotter. In the lamp as the first arc heats up, it begins to turn the solid mercury into a vapor, soon the arc is able to travel through the mercury vapor to reach the other main electrode on the opposite side of the discharge tube. There is less resistance on this path now and current stops flowing through the starting electrode, just as a river changes course to a path of least resistance, drying out the previous channel.

3.) After a mercury vapor arc strikes and heats, the halides vaporize and the halides dissociate. The metal atoms diffuse away from the arc to cooler areas and recombine with the halogen before they damage any part of the silica or electrodes. The lamp is now fully warmed up and produces its white light.

Metal halide work lamps are clearly visible in construction on the world trade center tower (there are no walls to block work lights yet in this photo)Construction Materials:

The high pressure and temperature of this light would normally react and destroy the silica in normal glass. Fused quartz is used due to a high melting temperature, and by using halogens the destructive process is stopped.

Tungsten has the highest melting point of any metal and therefore it makes the best electrode material. The tungsten is treated with radioactive thorium (Thl4)(ThO2). This helps increase the life of the tungsten and lamp itself.

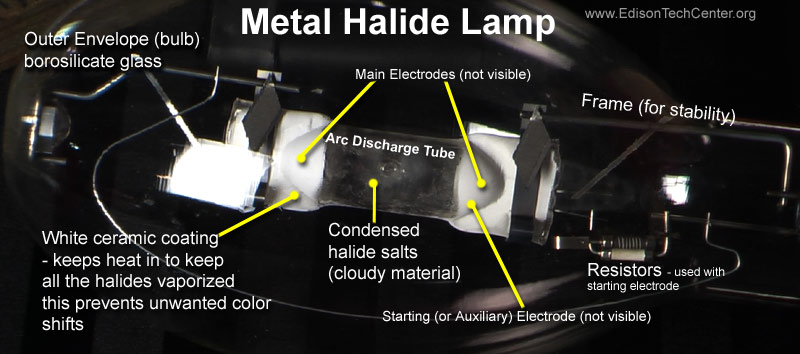

Metal halide is a favorite for sports field lighting

Borosilicate glass is used in the outer envelope (bulb) due to its ability to insulate as well as block UV-B radiation coming from the arc. The bulb also prevents users from touching and fouling the fused quartz discharge tube with oil from the skin. The mercury vapor arc in the metal halide lamp produces UV light. Borosilicate glass, also known as Pyrex insulates the lamp, insulating the lamp is extremely important to keep the color constant. Some halides have a lower vaporization point and will begin to drop out of the discharge if the lamp gets colder. The halides are designed in a balance to create the desired white light, loss of the the Agl halide for example will make the lamp turn more blue. Stabilizing the MH lamp arc and color was the main problem that Steinmetz wasn't equipped to solve in the first lamps of 1912.

Molybdenum is used in the seal of the discharge tube because it does not expand or soften easy, even under extremely high temperatures. Expansion of the electrode coming out of the discharge tube would crack or break the sealed tube which forms a flat seam on each end. Molybdenum is also highly resistant to corrosion and is also used in high strength steel, armor and electrical contacts.

Metal halide work lights on the Hudson River. You can clearly see the power of HID lamps here. Only spot and search lights are more powerful.

The first MH lamps had a large outer envelope. In the last 20 years engineers have been able to make a smaller MH lamp at higher pressures. The higher pressure means a higher efficiency as well.

Left: 1 cm diameter MH lamp used in a hand held flashlight.Smaller sized bulbs with lower wattages have allowed for wider application of uses. The smaller bulbs are used in hand held flash lights (they are not very popular since they require a large battery (1+ kilo), but they do make the most powerful hand held light available). Smaller MH bulbs have an extremely high pressure up to 700 PSI (4,826,325 Pascal).

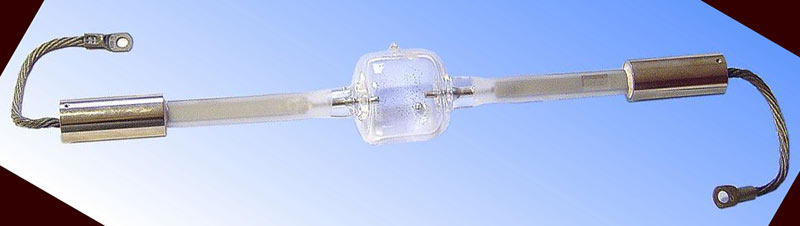

Venture Lighting International MH lamp: this is a pulse start model, pulse start is normally used with HPS lamps. It uses an igniter to create a high voltage pulse. This model has a shield to diffuse light and prevent damage to the lamp if the lamp explodes (this can happen at the end of life).

Use in car headlights:

The MH lamp has been used in Europe for automobile headlights for some time. It recently has recently become legal to use as an automotive headlight in the US. These lamps cast a cooler light with a poorer color rendering index than Halogen. This light is brighter and has created controversy as it may make the road more dangerous by blinding other drivers. This head light is sometimes confused with the Sylvania "Bright Star" which is a Halogen headlight with a blue filter.

Notice the different color temperatures below. The moving car on the left has an HID light about 6000K (bluish), the other to the right has normal halogen tungsten lamp, about 3000K. The street lights are a warmer colored metal halide, about 3000K.

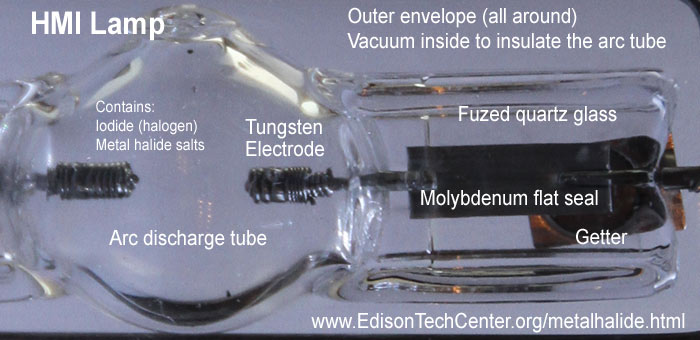

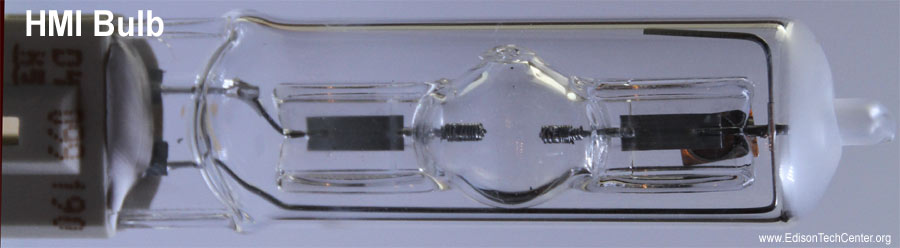

The HMI

Another kind of metal halide lamp is the halogen metal iodide or HMI lamp. It is mainly used for photography since it makes a 5600 K light (matching natural daylight) and has a great CRI. The lamp has a optimum combination of metal halides made of rare earth metals. It has a quartz discharge tube with rod-shaped electrodes made of tungsten and a power supply of high voltage DC. The external ballast is rather heavy, about 6+ pounds. The light is best used as a powerful light source at 8+ ft (2 m) distance from the talent. This light is expensive and in demand among the film and television industry professionals. 90 lumens per watt.

Above: Diagram of an HMI lamp. The arc discharge tube is inside the larger outer evelope. A getter is left inside during manufacture to remove all the impurities left, this helps make a true vacuum. The vacuum insulates the arc tube, so that it stays hot and colors don't shift. FYI: Iodide halogen was the first halogen used in the incandescent halogen lamp.

Above: A Short-arc Metal Halid Lamp. Photo: Lamptech.co.uk

Short-arc Metal Halide (MEI)

The Short Arc metal halide lamp is similar to the xenon short-arc lamp in appearance. It is a glass tube with a bulging center bulb with two tungsten electrodes. The high pressure bulb is made of clear quartz and boasts over 100 lumens per watt(due to the higher pressure). The bulb is touted as the "most powerful discharge lamp in widespread use". It uses a Dysprosium iodide and mercury filling in the tube. 6000 K / CRI 95

If you know who developed the Short-arc MH lamp please contact us so that we may honor him/her in our inventor section below.

Photo: LUXIMThe LEP is a high intensity light which is often put in a parallel with the LED. The LEP is not the same, it is actually a form of metal halide lamp and induction lamp. It has a high pressure quartz bulb that contains metal halides and no electrodes. This bulb is nestled in a unit that creates radio frequency energy and directs it into the bulb. The halides are vaporized and light is made, on the back side of the quartz bulb is a highly reflective powder. This light has a potential for longer life than the standard metal halide because it has a perfectly sealed bulb with no electrodes penetrating the envelope.

This lamp can be used for street lighting, film lighting and other applications which need intense lighting equivalent to the HPS or MH lamps.

Companies: Luxim, Topang Technologies

Life:

- Using magnetron: up to 40,000 hrs, normally 20,000 hrs.

- Using solid chips to make the RF: longer than 20,000 hrs.The LEP is related to the HEP lamp listed on our Induction Lamps page.

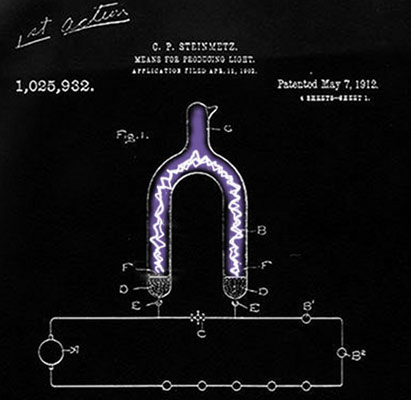

1912 Charles P. Steinmetz is the first to use halide salts in a mercury vapor lamp. He used the halides to correct color and was successful, but he could not get a consistent arc. The complex phenomena of plasma physics was still being explored. Steinmetz's arc would dance around allowing the temperature in the discharge tube to drop, the lower temperatures would stop the halide salts from burning and the color and intensity of the lamp would shift.

Schenectady, New York

Photo: Edison Tech Center

1962 Robert Reiling used recent developments in the high pressure mercury vapor lamp to create the first reliable MH lamp. A fused quartz discharge tube with molybdenum and tungsten sealed electrodes were just developed to deal with the destructive high temps of high pressure mercury lamps. Reiling built on the work of Steinmetz to complete the work. The MH lamp became more popular decades later as the price of the lamp became more affordable.

General Electric. Schenectady, New York

Photo: The Schenectady Museum

2001 Frederick Espiau, Chandrashekhar Joshi & Yian Chang invented the LEP or lighting emitting plasma lamp. (Luxim Corp.) The lamp could be considered both a metal halide lamp and electrodeless induction lamp. The lamp has not reached full market potential yet since it is so new. Also see HEP lamps which are related.

Sunnyvale, California

|

|

|

Lamps are presented in the order of chronological development

|

Previous: LED 1962 |

Next: Induction Lamps 1994 |

|

|

Arc

- Incandescent - Nernst

- Neon - Mercury

Vapor - Sodium Lamp - Fluorescent

- Halogen - EL

- LED - MH

- Induction

|

Donate to keep us online

COMMENTS?

Help us edit and add to this page by becoming a ETC volunteer!

Give us feedback on this and other pages using our Facebook

Page

Sources:

Smithsonian Institute

Luxim

Lamptech.co.uk

Wikipedia

Lighting a Revolution: Charles Steinmetz's Metal Halide Patent

Venture Lighting

Photos

provided by:

Edison Tech Center. Photographer M. Whelan

Schenectady Museum archives

Lamptech.co.uk

LUXIM

Photo/Video

use:

Commercial entities must pay for use of photos/graphics/videos in their

web pages/videos/publications

No one commercial or public is allow to alter Edison Tech Center photos/graphics/videos.

Educational Use: Students and teachers may use photos and videos

for school. Graphics and photos must retain the Edison Tech Center watermark

or captions and remain unmanipulated except for sizing.

Permissions

- Videos: We do not email, FTP, or send videos/graphics to anyone

except in DVD form. Payment is needed for this service. See our donate

page for pricing, and our catalogue

for a listing of videos on DVD.

Professional video production companies may get videos in data form with

signed license agreements and payment at commercial rates.

Back

to Home

Copyright

2012 Edison Tech Center